Description of Gas Drive Pump

The operating mechanism of the Gas Drive Pump is different from other pumps used by the oil and gas industry. The GDP has no surface equipment. The GDP uses a proven design concept known as "mechanical advantage". Mechanical advantage effectively magnifies down hole pressure creating a pump. The GDP consists of a series of natural gas driven pistons. The pistons are configured to create a pump driven by natural gas. By sequencing larger pistons driven by natural gas to oppose a smaller piston (acting as a liquid pump) the existing reservoir pressure at the bottom of the well is magnified by a factor of up to 15X creating lift. The GDP requires some natural gas production to drive the pistons. If the well does not have sufficient natural gas, natural gas can be injected into the well bore through a capillary string. The GDP can be used in vertical and deviated (horizontal) wells. It can lift up to 50 barrels of liquid per day.

The Gas Drive Pump is Lifteck's solution to mitigating the problems caused by liquid loading, and represents a novel advancement in gas production technology. The solution is based on the use of a down hole pump driven by pressure from the gas reservoir to bring the produced liquids from the reservoir to the surface, thereby controlling the liquid loading, arresting the decline in gas flow and maintaining consistent gas production through the well casing.

The innovative features of the pump make it a cut above most solutions to liquid loading available in the market today - it is submersible, and is connected to the end of the jointed tubing or to coiled tubing, hence there is no surface equipment, no well bore modification is required, and there is no noise. It can be used in vertical or highly deviated wells, and will work at most angles. Running on reservoir gas pressure, it needs no external power source, and there are no electrical parts. It will require some maintenance typical for other pumps relating to scaling and/or formation contaminants. Besides pumping water out of the wells, it can also pump oil if necessary. An estimated working life of 12- 24 months (competition average 3-12 months) means that the GDP is cheaper and will significantly reduce the wells down time because of the frequent shutdowns for replacement installations."Lifteck is based in Calgary, Canada. Lifteck designs, manufactures, and installs state-of-the-art mechanical advantage pumps for the oil and gas industry.

Gas Drive Pump Features:

- Powered by reservoir gas pressure only

- No external power required

- Can operate in remote locations

- Pumps liquids from gas wells or high GOR oil wells, even with low flowing bottomhole pressure

- Very low maintenance

- Usually no wellbore modification required for installation

- Normal installation has no surface equipment and therefore does not generate noise

- Screen on liquids intake prevents solids from entering the pump

- GD Pump system can be used in vertical or highly deviated wells

- Packer must be set at a location above where the wellbore angle first reaches 90 degrees

- Packer can be separated from the pump by a number of extension pipes

- Pump will operate at any angle, from vertical to horizontal

-

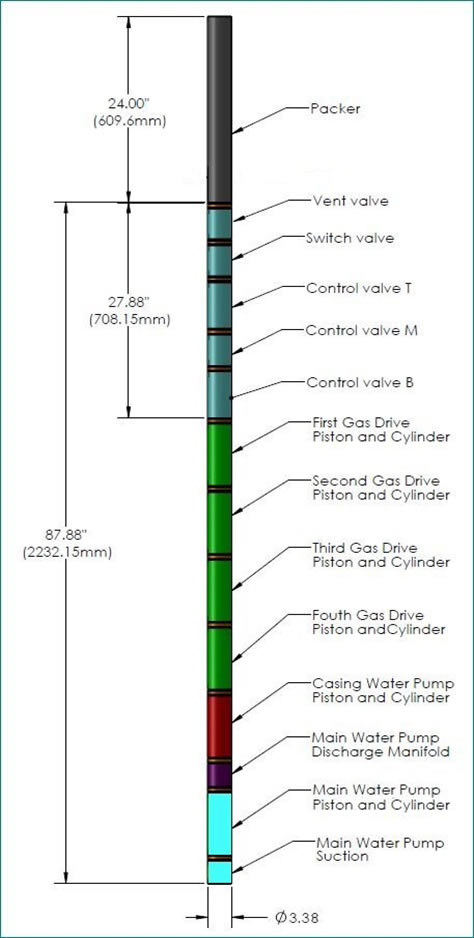

Schematic

Schematic

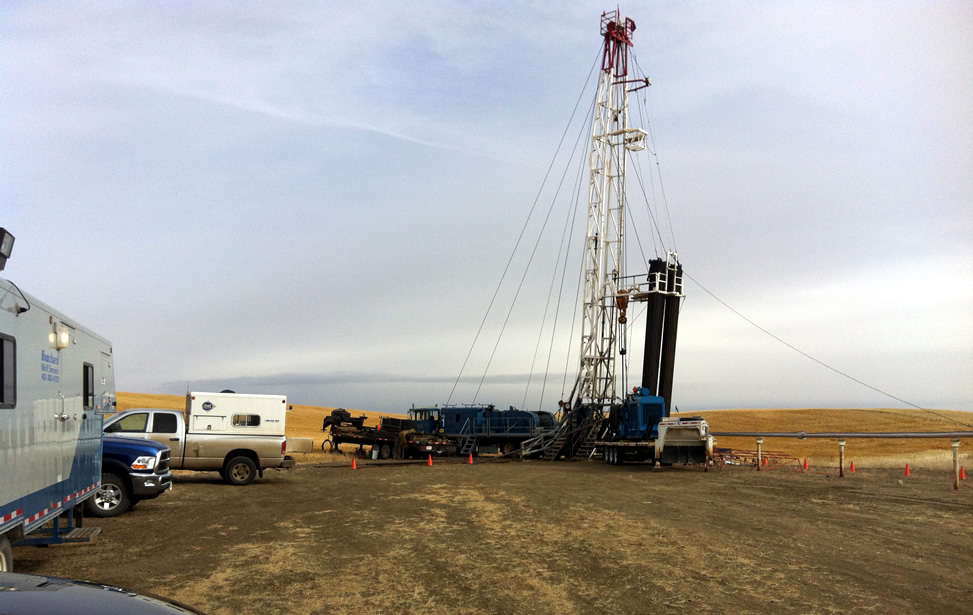

Installation Photos

-

Alberta, Canada

Alberta, CanadaVertical Well

Lifteck pump being installed with a service rig in southeast Alberta

-

Saskatchewan, Canada

Saskatchewan, Canada45° Deviated Well

Lifteck pump being installed in a deviated well with coiled tubing in SW Saskatchewan

-

Alberta, Canada

Alberta, CanadaVertical Well

Flow line rig-in after installation of Lifteck pump